86-513-81188826

86-513-81188821

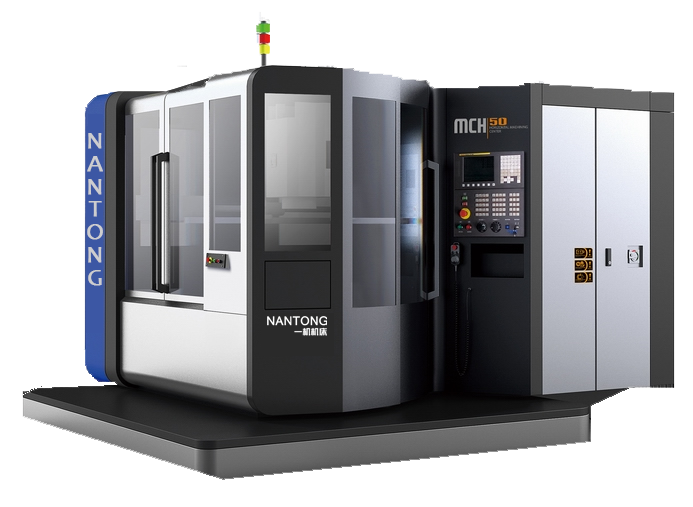

YJ-H50 |

|

|

First, product information CNC machine tool products, the standard BT50 spindle, the machine bed as a whole casting, can be a variety of different configurations, enabling four-axis four-linkage, widely used in military, aerospace, automotive, mold, machinery manufacturing and other parts of the box, Body parts, disk parts, shaped parts processing, parts by a folder can be automatically completed four milling, boring, drilling, expanding, reaming, tapping and other processes, to ensure the accuracy and efficiency of processing. T-shaped body as a whole above the front of the bed bed saddle, table saddle along the bed of the linear guide moves left and right for the X-axis direction, the bed above the rear column, the column along the bed body linear guide back and forth to Z axis Direction, the milling head moves up and down in the column for the Y axis direction, table rotation (B axis) can be divided into indexing and CNC turntable. The company is located in: Second, the performance characteristics 1, the overall casting bed, the design process through finite element analysis to make the product structure more reasonable, due to the overall casting, making the machine with cutting rigidity, smooth cooling liquid flow recovery, the overall sealing machine and many other advantages, the whole machine weighed 12 tons more shows the high rigidity of the machine. 2, the main motor, such as the use of FANUC wide area motor, through the motor into the line connection changes, both for high-speed machining, but also to achieve low-speed high-torque cutting; 3, three linear axes using wide-load heavy linear guide, to ensure the rigidity of the whole cutting; 4, the rotary table with four taper pin positioning method to ensure that the machine when cutting dynamic positioning accuracy. (Double exchange table); 5, Clever installation of knife location, water, easy cleaning, the bottom of the magazine for the machine chip conveyor, just to finish the tool out of the water, the chip just fell in the chip conveyor; 6, reserved grating position. According to user needs, when ordering can increase the grating ruler, improve machine positioning accuracy, repeat positioning accuracy. The company is located in: YJ-H50 horizontal machining center main technical parameters name unit stroke X-axis travel mm 700 Y-axis travel mm 580 Z axis travel mm 580 Countertop to spindle center distance mm 110-690 Spindle end to table center distance mm 120-700 Workbench Workbench area mm 500 × 500 Workbench maximum load-bearing kg 500 Spindle Spindle speed r / min 60-6000 Spindle hole taper - BT50 Rotate the workbench Turntable maximum speed r / min 5 Turntable (B axis) indexing 1 Feed rate X / Y / Z axis rapid displacement m / min twenty four Cutting feed rate mm / min 1-10000 Automatic tool change system (disc type) Number of tools pcs twenty four Tool change time (knife - knife) sec 3.27 Maximum tool length mm 350 The maximum diameter of the tool mm 120 (full knife) 200 (adjacent knife) 230 (adjacent no knife) The maximum weight of the tool kg 18 Motor Spindle motor kw 9/11 (11/15) X / Y / Z motor Nm 22/30/22 Turntable motor Nm 8 Hydraulic station motor power kw 4 Cold pump motor kw 0.4 Accuracy (refer to JB / T8771.4-1998 standard) Positioning accuracy X / Y / Z mm 0.01 Repeatability mm 0.006 Turntable positioning accuracy 12 " Turntable repeat positioning accuracy 6 " Machine size Machine dimensions (length × width × height) mm 2810 Iron box dimensions (L × W × H) mm 4000 × 2600 Machine weight / gross weight kg 12000 electricity demand KVA 40 working environment Ambient temperature ℃ -5-45 Relative humidity 0-90% Air pressure Mpa 0.6 Hydraulic system working pressure Mpa 5.3 power supply 50Hz 380V ± 10% |